Zhiyang Machinery

Zhiyang Machinery

0519-88674267/88674627

czzy2015@vip.163.com

No. 113 Huanzhen Road

Search The Product

Search The Product

Products

Products

Features:

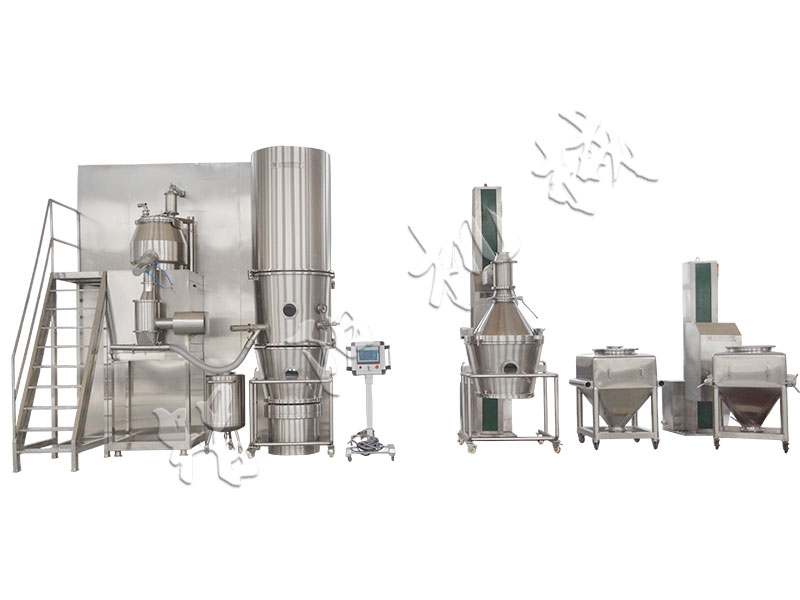

● Through powder granulation, improve fluidity and reduce dust flying;

● Improve its dissolving performance through powder granulation;

● Mix, granulate and dry in one machine to complete one-step granulation;

● Using antistatic filter cloth, the equipment is safe to operate;

● Explosion-proof pressure relief holes are provided, and equipment personnel will not be harmed if an explosion occurs;

● The equipment has no dead corners, the loading and unloading is light and fast, and it is cleaned to meet GMP specifications.

★ Application:

● Granulation in the pharmaceutical industry: tablet granules, granules, capsule granules.

● Granulation in the food industry: cocoa, coffee, milk powder, granulated juice, condiments, etc.

● Granulation in other industries: pesticides, feed, fertilizers, pigments, dyestuff chemicals, etc.

● Drying of powdery or granular wet materials.

● Coating: granule, protective layer of pills, coloring, sustained release, film, enteric coating, etc.

working principle:

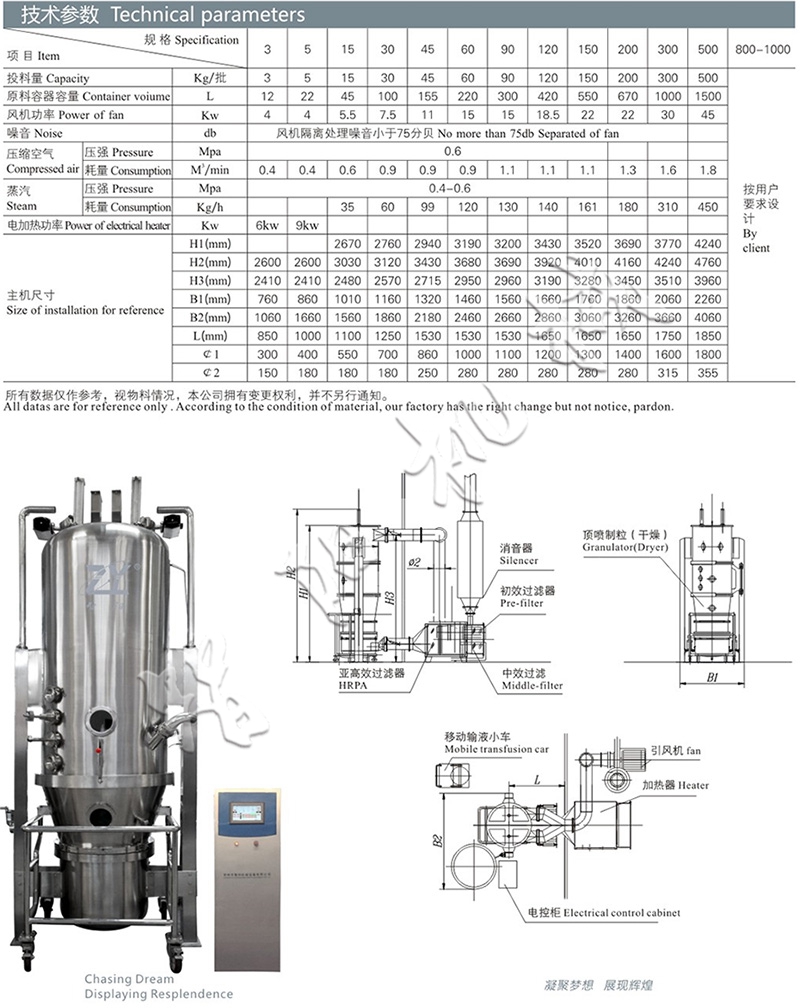

● The material powder particles are in a circular fluidized state in the raw material container (fluidized bed). They are preheated and mixed by purified heated air, and the binder solution is atomized and sprayed, so that several particles are aggregated into a binder. Due to the continuous drying of the material by hot air, the moisture in the pellets evaporates and the binder solidifies. This process is continuously repeated to form ideal and uniform microporous spherical particles.

Follow Us

Follow Us