Zhiyang Machinery

Zhiyang Machinery

0519-88674267

czzy188@163.com

Tianning Zhihuigang, No. 65 Shunshan Road, Sanhekou, Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province

Search The Product

Search The Product

项目案例

项目案例

Application:

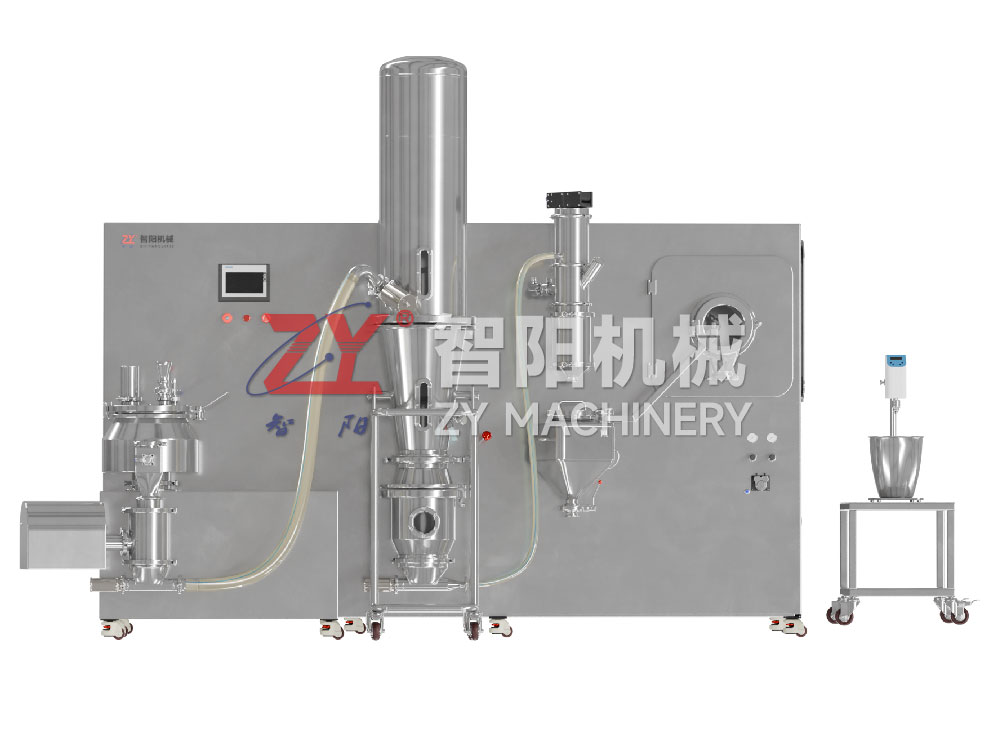

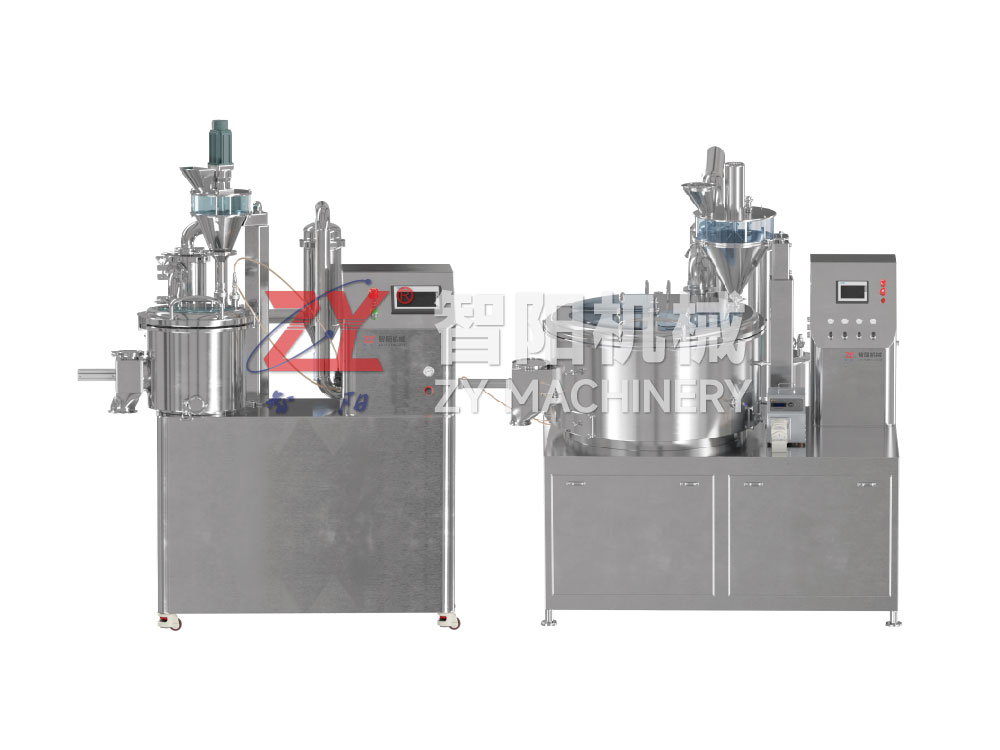

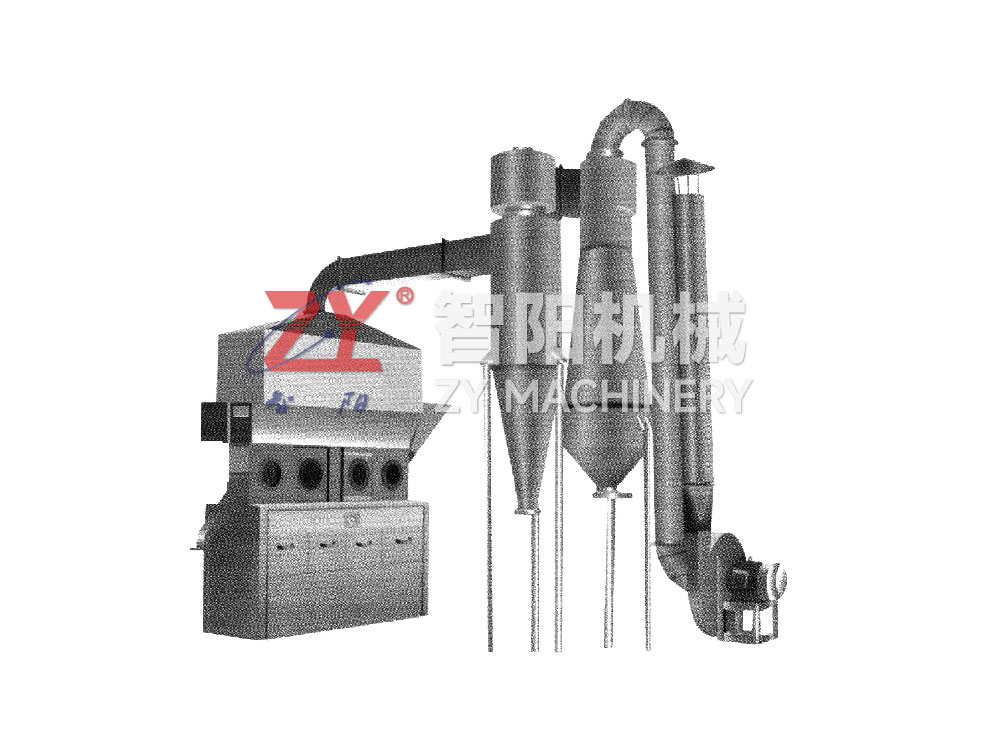

● Fluidized bed coating machine is a new type of particle coating equipment that organically combines fluidized coating technology and spray technology. It is widely used in membrane controlled release, matrix sustained controlled release capsule, pill coating, granules, powder Coating.

Features:

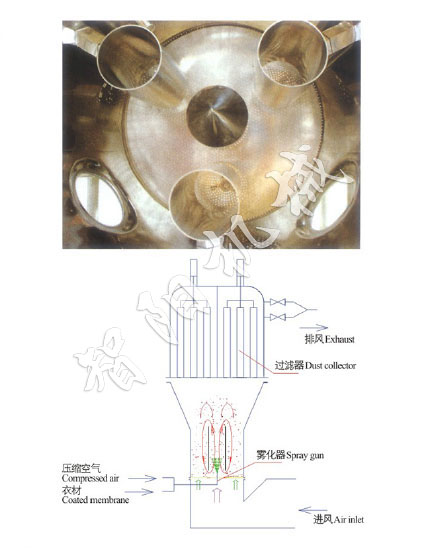

● The bottom spray is fluidized, and the material has a certain regular trajectory, so a uniform and continuous coating film can be obtained.

● Powder, granule, pill masking, moisture-proof, anti-oxidation, water-proof, heat-proof, coloring, etc

● No coating material loss and low production cost.

● The mist particles reach the material line short, and there is no "spray drying"

● Cylindrical acceleration container or inverted cone deceleration design can be used for coating of particles, large particles, small particles and pellets.

● The material has excellent dispersion and no blocking phenomenon.

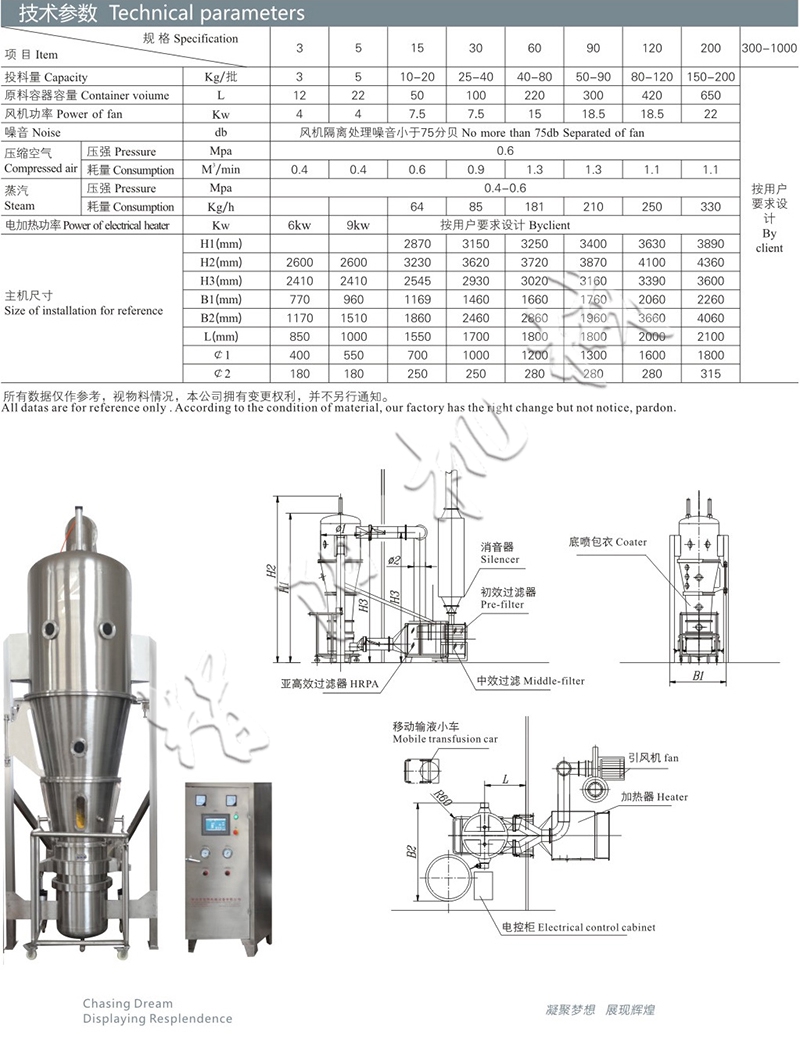

| Specification | LDP-3 | LDP-5 | LDP-15 | LDP-30 | LDP-60 | LDP-90 | LDP-120 | LDP-200 | LDP-300-1000 | ||

Item | |||||||||||

Feeding amount | Kg/h | 3 | 5 | 10-20 | 25-40 | 40-80 | 50-90 | 80-120 | 150-200 | Design according to user requirements | |

Raw material container capacity | L | 12 | 22 | 50 | 100 | 220 | 300 | 420 | 650 | ||

Power of fan | Kw | 4 | 4 | 7.5 | 7.5 | 15 | 18.5 | 18.5 | 22 | ||

Noise | db | Fan isolation processing noise is less than 75dB | |||||||||

Compressed air | Pressure | Mpa | 0.4-0.6 | ||||||||

Compressed air | Consumption | M3/min | 0.4 | 0.4 | 0.6 | 0.9 | 1.3 | 1.3 | 1.1 | 1.1 | |

Steam | Pressure | Mpa | 0.4-0.6 | ||||||||

Consumption | Kg/h |

|

| 64 | 85 | 181 | 210 | 250 | 330 | ||

Electric heating power | Kw | 9kw | 6kw | Design By client according to user requirements | |||||||

Host size | H1(mm) |

|

| 2870 | 3150 | 3250 | 3400 | 3630 | 3890 | ||

Size of installation for reference | H2(mm) | 2600 | 2600 | 3230 | 3620 | 3720 | 3870 | 4100 | 4360 | ||

H3(mm) | 2410 | 2410 | 2545 | 2930 | 3020 | 3160 | 3390 | 3600 | |||

B1(mm) | 770 | 960 | 1169 | 1460 | 1660 | 1760 | 2060 | 2260 | |||

B2(mm) | 1170 | 1510 | 1860 | 2460 | 2860 | 1960 | 3660 | 4060 | |||

L(mm) | 850 | 1000 | 1550 | 1700 | 1800 | 1800 | 2000 | 2100 | |||

¢1 | 400 | 550 | 700 | 1000 | 1200 | 1300 | 1600 | 1800 | |||

¢2 | 180 | 180 | 250 | 250 | 280 | 280 | 280 | 315 | |||

All data are for reference only, depending on the material, the company has the right to change without notice

- Prev:FL-B boiling granulator (one-step granulator)

- Next:没有了!

Follow Us

Follow Us